Ihe e ji ihe mejupụtara ígwè siri ike nke na-anaghị emegharị ahụ na ígwè na-ejikọta ihe site na usoro ígwè ntụ ntụ. Carbide e ji simenti mee nwere ọtụtụ ihe ndị dị mma dịka ike siri ike, ike iyi, ike na ike dị mma, ike okpomọkụ na iguzogide nchara, karịsịa ike siri ike ya na ike iyi ya, nke na-agbanweghi agbanwe ọbụlagodi na okpomọkụ nke 500 °C, ka nwere ike siri ike na 1000 ℃. A na-ejikarị Carbide eme ihe dị ka ihe eji arụ ọrụ, dị ka ngwaọrụ ntụgharị, ihe e ji egwe ihe, ihe e ji atụgharị ihe, ihe e ji eme ihe, ihe e ji emegharị ihe, ngwaọrụ na-agwụ ike, wdg, maka ịkpụ ígwè a kpụrụ akpụ, ọla ndị na-abụghị ferrous, plastik, eriri kemịkalụ, graphite, iko, nkume na ígwè nkịtị, a pụkwara iji ya gbue ihe ndị siri ike iji igwe rụọ dịka ígwè na-anaghị eguzogide okpomọkụ, ígwè anaghị agba nchara, ígwè manganese dị elu, ígwè ngwaọrụ, wdg. Ọsọ mbelata nke ngwaọrụ carbide ọhụrụ ugbu a bụ narị narị ugboro karịa ígwè carbon.

Ojiji nke carbide simenti

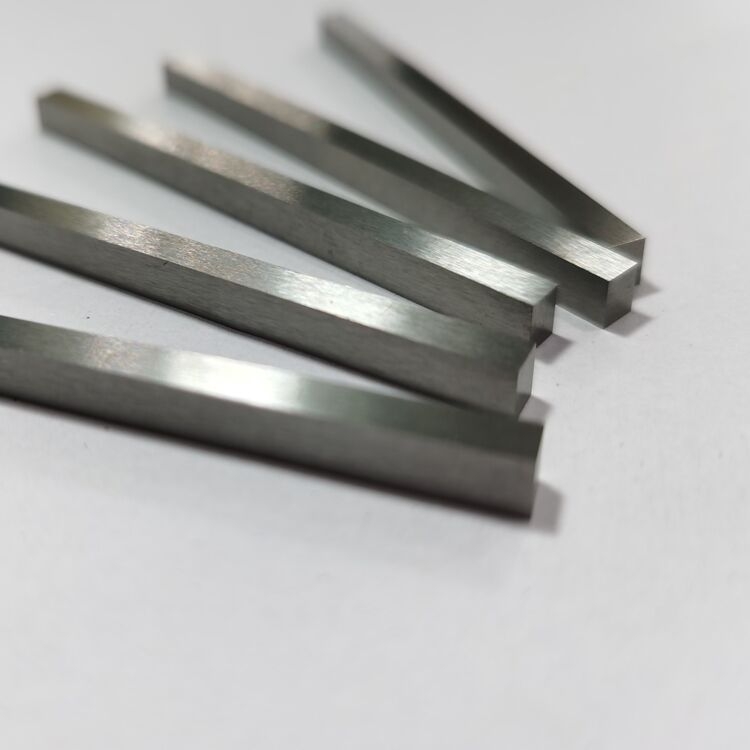

(1) Ihe eji arụ ọrụ

Carbide bụ ngwa ọrụ kachasị ukwuu, nke enwere ike iji mee ngwa ntụgharị, igwe e ji egwe ihe, ihe eji atụgharị ihe, ihe eji eme ihe, wdg. N'ime ha, tungsten-cobalt carbide dabara adaba maka nhazi obere chip nke ígwè ferrous na nke na-abụghị ferrous na nhazi nke ihe ndị na-abụghị ọla, dị ka ígwè a kpụrụ akpụ, ọla kọpa a kpụrụ akpụ, bakelite, wdg.; tungsten-titanium-cobalt carbide dabara adaba maka nhazi ogologo oge nke ígwè ferrous dị ka ígwè. Ịkpụcha chip. N'etiti ihe ndị yiri ya, ndị nwere ọtụtụ cobalt dị mma maka ịkpụcha siri ike, ndị na-enweghị obere cobalt dị mma maka imecha. Carbides simenti e ji eme ihe n'ozuzu nwere ndụ ịkpụcha ogologo oge karịa carbide ndị ọzọ e ji simenti mee maka ihe ndị siri ike iji igwe dị ka ígwè anaghị agba nchara.

(2) Ihe e ji ebu ebu

A na-ejikarị carbide simented eme ihe maka ihe eji arụ ọrụ oyi dịka ihe eji ese ihe oyi, ihe eji akụ ọkpọ oyi, ihe eji egbutu oyi, na ihe eji egbutu oyi.

A chọrọ ka ihe mkpuchi isi oyi nke Carbide sie ike nke ọma, ike mgbawa, ike ọgwụgwụ, ike mgbagọ na ezigbo ike iyi n'okpuru ọnọdụ ọrụ na-eguzogide iyi ma ọ bụ mmetụta siri ike. A na-ejikarị ọkwa cobalt na ọkara na nke siri ike nke ọka, dị ka YG15C.

N'ozuzu, mmekọrịta dị n'etiti iguzogide iyi na ike nke carbide simenti na-emegiderịta onwe ya: mmụba nke iguzogide iyi ga-eduga na mbelata nke ike, mmụba nke ike ga-edugakwa na mbelata nke iguzogide iyi. Ya mere, mgbe ị na-ahọrọ akara alloy, ọ dị mkpa imezu ihe achọrọ maka ojiji dịka ihe nhazi na ọnọdụ ọrụ nhazi si dị.

Ọ bụrụ na ọkwa ahọpụtara na-enwe ike ịgbawa n'oge ma mebie n'oge ojiji, a ga-ahọrọ ọkwa nwere ike dị elu; ọ bụrụ na ọkwa ahọpụtara na-adịkarị mfe iyi na mmebi n'oge ojiji, a ga-ahọrọ ọkwa nwere ike dị elu na iguzogide iyi ka mma. . Akara ndị a: YG15C, YG18C, YG20C, YL60, YG22C, YG25C Site n'aka ekpe gaa n'aka nri, ike ya na-ebelata, ike ya na-ebelata, ike ya na-abawanye; n'ụzọ megidere nke ahụ, ihe dị iche bụ eziokwu.

(3) Ngwaọrụ nha na akụkụ ndị na-anaghị eyi uwe

A na-eji Carbide eme ihe maka ihe ndị na-anaghị emebi emebi na akụkụ ngwaọrụ nha, ihe ndị na-eji ígwè agwakọta ihe nke ọma, efere nduzi na mkpara nduzi nke ihe ndị na-anaghị agwakọta ihe n'etiti, elu lathes na akụkụ ndị ọzọ na-anaghị emebi emebi.

Ọla ndị na-ejikọta ihe bụ ọla ígwè, nke a na-akpọkarị cobalt na nickel.

Mgbe a na-emepụta carbide e ji simenti mepụta, nha nke ntụ ihe eji emepụta ihe ahọpụtara dị n'etiti 1 na 2 microns, ịdị ọcha ya dịkwa oke elu. A na-agwakọta ihe ndị a dịka oke nhazi e nyere, a na-agbakwụnyekwa mmanya ma ọ bụ ihe ndị ọzọ na igwe e ji agwakọta mmiri n'ime igwe ihe eji emepụta bọọlụ mmiri iji mee ka ha gwakọta ma gwerie ha nke ọma. Ghee ngwakọta ahụ. Mgbe ahụ, a na-etinye ngwakọta ahụ na granulated, pịa ya, ma kpoo ya ọkụ ruo n'okpomọkụ dị nso na ebe agbaze nke ígwè ihe eji emepụta ihe (1300-1500 °C), usoro siri ike na ígwè ihe eji emepụta ihe ga-emepụta ihe eutectic alloy. Mgbe ọ jụrụ oyi, usoro siri ike na-ekesa na grid nke mejupụtara ígwè ihe eji emepụta ihe ma jikọta onwe ha nke ọma iji mepụta ihe siri ike. Ike nke carbide e ji simenti mee dabere na ọdịnaya usoro siri ike na nha ọka, ya bụ, ka ọdịnaya usoro siri ike na ka ọka ndị ahụ sikwuo ike, otú ahụ ka ike na-esiwanye ike. A na-ekpebi ike nke carbide e ji simenti mee site na ígwè ihe eji emepụta ihe. Ka ọdịnaya ígwè ihe eji emepụta ihe dị elu, otú ahụ ka ike na-esikwu ike.

Na 1923, Schlerter nke Germany tinyere pasentị iri ruo pasentị iri abụọ nke cobalt na ntụ tungsten carbide dị ka ihe na-ejikọ ihe, wee mepụta ihe ọhụrụ nke tungsten carbide na cobalt. Ike ya dị n'etiti naanị dayamọnd. Carbide mbụ e ji simenti mee mere. Mgbe a na-eji ngwaọrụ e ji alloy a mee egbutu ígwè, ọnụ ụzọ ya ga-aka njọ ngwa ngwa, ọbụnakwa ọnụ ụzọ ya ga-agbawa agbawa. Na 1929, Schwarzkov na United States tinyere ụfọdụ carbide tungsten carbide na titanium carbide compound na ihe mejupụtara ya, nke mere ka arụmọrụ nke ngwaọrụ ahụ ka mma n'ịkpụ ígwè. Nke a bụ ihe ọzọ a rụzuru n'akụkọ ihe mere eme nke mmepe carbide simenti.

Carbide e ji simenti rụọ nwere ọtụtụ ihe ndị dị mma dịka ike siri ike, ike iyi, ike na ike dị mma, ike okpomọkụ na iguzogide nchara, karịsịa ike siri ike ya na ike iyi ya, nke na-agbanweghi agbanwe ọbụlagodi na okpomọkụ nke 500 °C, ka nwere ike siri ike na 1000℃. A na-eji Carbide eme ihe dị ka ihe eji arụ ọrụ, dịka ngwaọrụ ntụgharị, ihe e ji egwe ihe, ihe e ji atụgharị ihe, ihe e ji eme ihe, ihe e ji emegharị ihe, ngwaọrụ na-agwụ ike, wdg, maka ịkpụ ígwè a kpụrụ akpụ, ọla ndị na-abụghị ferrous, plastik, eriri kemịkalụ, graphite, iko, nkume na ígwè nkịtị, a pụkwara iji ya gbue ihe ndị siri ike iji igwe rụọ dịka ígwè na-eguzogide okpomọkụ, ígwè anaghị agba nchara, ígwè manganese dị elu, ígwè ngwaọrụ, wdg. Ọsọ mbelata nke ngwaọrụ carbide ọhụrụ ugbu a bụ narị narị ugboro karịa ígwè carbon.

A pụkwara iji Carbide mee ngwaọrụ igwu nkume, ngwaọrụ igwu ala, ngwaọrụ igwu ala, ngwaọrụ nha, akụkụ ndị na-adịghị emebi emebi, ihe nhicha ígwè, ihe mkpuchi silinda, ihe ndị e ji echekwa ígwè, ihe ndị e ji echekwa ígwè, ihe e ji echekwa ígwè (nozzles), ihe e ji adọta ígwè (dịka ihe e ji adọta ígwè, ihe e ji ejide ígwè, ihe e ji ejide mkpụrụ, na ihe e ji ejide ígwè dị iche iche, arụmọrụ dị mma nke carbide e ji simenti mee ji nwayọọ nwayọọ dochie ihe e ji arụpụta ígwè ndị gara aga).

Mgbe e mesịrị, a kpụchara simenti e ji ígwè mee ka ọ pụtakwara. Na 1969, Sweden mepụtara ngwa ọrụ e ji ígwè mee ka ọ dị ka titanium carbide nke ọma. Isi ihe dị na ngwa ọrụ a bụ tungsten-titanium-cobalt carbide ma ọ bụ tungsten-cobalt carbide. Ọkpụrụkpụ nke mkpuchi titanium carbide dị n'elu ya bụ naanị microns ole na ole, mana ma e jiri ya tụnyere otu ụdị ngwa ọrụ alloy ahụ, Ndụ ọrụ ya na-agbatị ugboro atọ, ọsọ ịkpụ ya na-amụba site na 25% ruo 50%. Na 1970s, ọgbọ nke anọ nke ngwaọrụ e ji ígwè mee pụtara maka ịkpụ ihe ndị siri ike iji igwe mee.

Kedu otu esi esi simenti simenti carbide?

Carbide simented bụ ihe e ji ígwè mee site na ntụ ntụ nke carbides na ígwè njikọ nke otu ma ọ bụ karịa ígwè ndị na-anaghị emegharị ahụ.

Mmba ndị na-emepụta ihe nke ọma

E nwere ihe karịrị mba iri ise n'ụwa na-emepụta carbide e ji simenti mepụta, nke nwere mkpokọta mmepụta nke 27,000-28,000t-. Ndị na-emepụta ihe bụ isi bụ United States, Russia, Sweden, China, Germany, Japan, United Kingdom, France, wdg. Ahịa carbide e ji simenti mepụta n'ụwa juputara na ya. Asọmpi ahịa dị oke njọ. Ụlọ ọrụ carbide e ji simenti mepụta nke China malitere ịmalite na ngwụcha afọ 1950. Site na afọ 1960 ruo afọ 1970, ụlọ ọrụ carbide e ji simenti mepụta nke China mepụtara nke ọma. Na mbido afọ 1990, ikike mmepụta zuru oke nke China nwere nke carbide e ji simenti mepụta ruru 6000t, mmepụta zuru oke nke carbide e ji simenti mepụta ruru 5000t, nke abụọ naanị na Russia na United States, ọ nọ n'ọkwa nke atọ n'ụwa.

Ihe eji egbutu WC

① Tungsten na cobalt simenti carbide

Ihe ndị bụ isi mejupụtara ya bụ tungsten carbide (WC) na binder cobalt (Co).

Ọkwa ya bụ "YG" ("siri ike na cobalt" n'asụsụ Chinese Pinyin) na pasentị nke nkezi ọdịnaya cobalt.

Dịka ọmụmaatụ, YG8 pụtara nkezi WCo = 8%, ebe ndị ọzọ bụ tungsten-cobalt carbide nke tungsten carbide.

mma TIC

②Tungsten-titanium-cobalt carbide

Ihe ndị bụ isi mejupụtara ya bụ tungsten carbide, titanium carbide (TiC) na cobalt.

E ji "YT" (“siri ike, titanium” mkpụrụedemede abụọ dị na prefix Pinyin nke ndị China) mee akara ya na nkezi ọdịnaya nke titanium carbide.

Dịka ọmụmaatụ, YT15 pụtara nkezi WTi=15%, ebe ndị ọzọ bụ tungsten carbide na tungsten-titanium-cobalt carbide nwere ọdịnaya cobalt.

Ngwaọrụ Tantalum Tungsten Titanium

③Tungsten-titanium-tantalum (niobium) carbide simenti

Ihe ndị bụ isi mejupụtara ya bụ tungsten carbide, titanium carbide, tantalum carbide (maọbụ niobium carbide) na cobalt. A na-akpọkwa ụdị carbide a nke e ji simenti mee ka ọ bụrụ carbide nkịtị ma ọ bụ carbide zuru ụwa ọnụ nke e ji simenti mee ka ọ bụrụ carbide.

E ji "YW" (nkọwa okwu ndị China nke "siri ike" na "wan" mee akara ya) tinyekwara nọmba usoro, dịka YW1.

Àgwà arụmọrụ

Ntinye Carbide Welded

Ike siri ike dị elu (86~93HRA, nke kwekọrọ na 69~81HRC);

Ezi ike okpomọkụ (ruo 900 ~ 1000℃, debe 60HRC);

Ezigbo iguzogide abrasion.

Ngwa eji egbutu ígwè kabọd dị ngwa ngwa karịa ígwè dị elu ugboro anọ ruo asaa, ndụ ngwaọrụ ahụ dịkwa elu ugboro ise ruo iri asatọ. Site n'ịmepụta ebu na ngwaọrụ nha, ndụ ọrụ ya dị elu ugboro iri abụọ ruo otu narị na iri ise karịa nke ígwè ejiri ihe alloy mee. Ọ nwere ike ịkpụ ihe siri ike nke ihe dị ka 50HRC.

Agbanyeghị, carbide e ji simenti mee na-agbawa agbawa ma enweghị ike iji ya rụọ ọrụ, ọ na-esikwa ike ime ngwaọrụ ndị nwere ọdịdị dị mgbagwoju anya. Ya mere, a na-emekarị agụba ndị nwere ọdịdị dị iche iche, nke a na-etinye n'ahụ ngwaọrụ ma ọ bụ ahụ ebu site na ịgbado ọkụ, njikọ, njide igwe, wdg.

Ogwe pụrụ iche

Sintering

Ihe e ji akpụ simenti nke e ji simenti mee bụ ịpịa ntụ ahụ n'ime billet, wee banye n'ime ọkụ sintering ka ọ kpoo ọkụ ruo okpomọkụ ụfọdụ (okpomọkụ sintering), debe ya ruo oge ụfọdụ (oge ijide), wee jụọ ya oyi iji nweta ihe simenti nke nwere ihe ndị dị mkpa.

A pụrụ ikewa usoro simenti nke carbide e ji simenti mee ụzọ anọ dị mkpa:

1: N'oge mwepụ nke ihe na-emepụta ihe na tupu nsị, ahụ gbawara agbawa na-agbanwe dịka ndị a:

Iwepụ ihe e ji akpụ ihe, ka okpomọkụ na-arị elu n'oge mbụ nke ịkpụ ihe, ihe e ji akpụ ihe ahụ na-agbaze ma ọ bụ na-ekupụ nwayọọ nwayọọ, a na-ewepụkwa ahụ e ji akpụ ihe ahụ. Ụdị, ọnụọgụ na usoro ịkpụ ihe dị iche.

A na-ebelata oxides dị n'elu ntụ ntụ ahụ. Mgbe okpomọkụ sintering na-apụta, hydrogen nwere ike ibelata oxides nke cobalt na tungsten. Ọ bụrụ na ewepụ ihe na-emepụta ihe na vacuum ma sintered, mmeghachi omume carbon-oxygen adịghị ike. A na-ewepụ nrụgide kọntaktị dị n'etiti ihe ntụ ntụ ahụ nwayọ nwayọ, ntụ ígwè ejikọtara na-amalite ịgbake ma na-emegharịghachi, mgbasa elu na-amalite ime, ike briquette na-akawanye mma.

2: Ogbo siri ike nke sintering (800℃–eutectic okpomọkụ)

N'ọnọdụ okpomọkụ tupu mmiri mmiri apụta, na mgbakwunye na ịga n'ihu na usoro nke ọkwa gara aga, mmeghachi omume siri ike na mgbasa na-eme ka ọ dịkwuo elu, a na-eme ka mmiri plastik dịkwuo mma, ahụ e ji ihe kpuchie na-ebelata nke ukwuu.

3: Ogbo mmiri mmiri mmiri mmiri (okpomọkụ eutectic - okpomọkụ sintering)

Mgbe mmiri mmiri pụtara n'ime ahụ a gbanyere mkpọrọgwụ, a na-emecha mbelata ahụ ngwa ngwa, wee mechaa mgbanwe kristal iji mepụta nhazi na nhazi nke ihe mejupụtara ya.

4: Ogbo oyi (okpomọkụ sintering - okpomọkụ ụlọ)

N'oge a, nhazi na nhazi nke alloy ahụ nwere mgbanwe ụfọdụ yana ọnọdụ oyi dị iche iche. Enwere ike iji atụmatụ a kpoo carbide simenti iji melite njirimara anụ ahụ na nke mekaniki ya.

Oge ozi: Eprel-11-2022