Bịa mụta maka HSS

Ígwè dị elu (HSS) bụ ígwè e ji arụ ọrụ nke nwere ike siri ike, ike iyi ya dị elu na oke okpomọkụ, nke a makwaara dịka ígwè ikuku ma ọ bụ ígwè dị nkọ, nke pụtara na ọ na-esi ike ọbụlagodi mgbe ọ jụrụ oyi n'ikuku n'oge a na-emenyụ ya ma dịkwa nkọ. A na-akpọkwa ya ígwè ọcha.

Ígwè dị elu bụ ígwè alloy nwere ihe mejupụtara ya dị mgbagwoju anya nke nwere ihe ndị na-akpụ akpụ carbide dịka tungsten, molybdenum, chromium, vanadium na cobalt. Ọnụọgụ ihe ndị na-agwakọta ya ruru ihe dị ka 10 ruo 25%. Ọ nwere ike ịnọgide na-enwe ike siri ike n'okpuru okpomọkụ dị elu (ihe dị ka 500℃) na mbelata ọsọ dị elu, HRC nwere ike ịdị elu karịa 60. Nke a bụ njirimara kachasị mkpa nke HSS - ike uhie. Ígwè carbon site na imenyụ na mbelata okpomọkụ dị ala, na okpomọkụ ụlọ, ọ bụ ezie na enwere ike dị elu, mana mgbe okpomọkụ dị elu karịa 200 ℃, ike ahụ ga-ada nke ukwuu, na 500 ℃ ike ahụ adalatala ruo n'ókè yiri nke ahụ na ọnọdụ annealed, efunahụla ikike ịkpụ ígwè kpamkpam, nke na-egbochi ngwaọrụ ịkpụ ígwè ígwè. Ígwè dị elu n'ihi ike uhie dị mma, iji mejupụta adịghị ike nke ígwè ngwaọrụ carbon.

A na-ejikarị ígwè dị elu arụ ọrụ iji mepụta ngwaọrụ ịkpụ ígwè dị mgbagwoju anya nke nwere ọnụ dị gịrịgịrị ma na-eguzogide mmetụta, kamakwa iji mepụta ihe ndị na-eme ka okpomọkụ dị elu na ihe ndị na-eme ka oyi na-atụ, dị ka ngwaọrụ ntụgharị, ihe eji eme ihe, ihe na-eme ka ihe dị n'ime ite, agụba igwe na ihe ndị na-achọ mma.

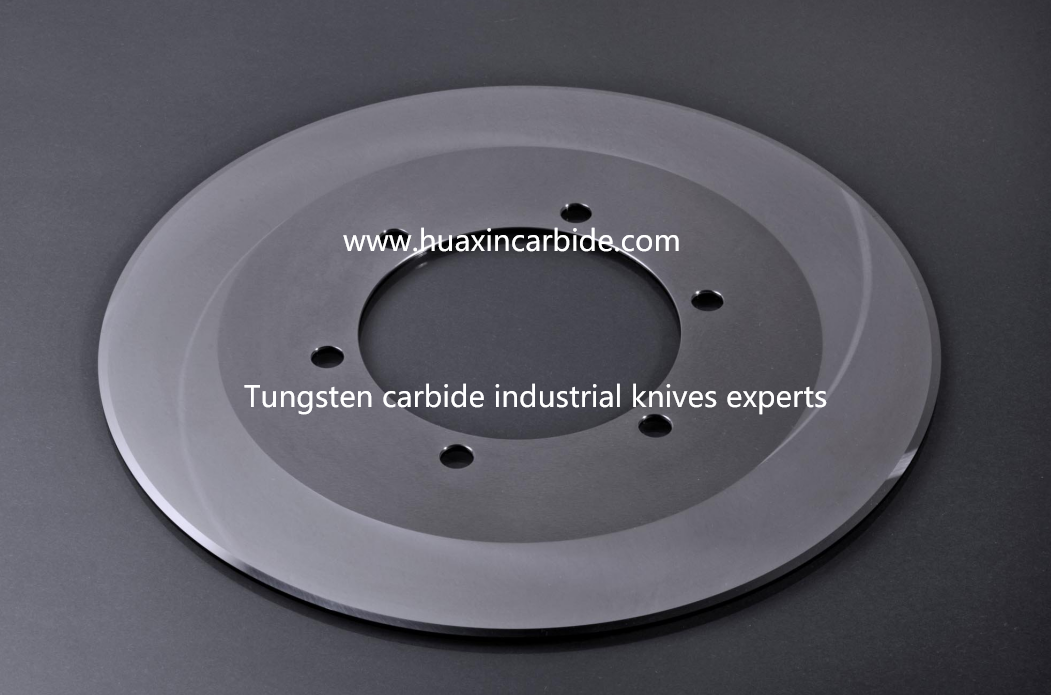

Bịa mụta maka ígwè tungsten

Ọkpụkpọ Tungsten (carbide) nwere ọtụtụ ihe ndị dị mma dịka ike siri ike, ike iyi, ike na ike ka mma, ike okpomọkụ, ike nchara, wdg. Karịsịa ike siri ike na ike iyi ya na-agbanweghi agbanwe ọbụlagodi na okpomọkụ nke 500℃, ma ka nwere ike siri ike na 1000℃.

E ji ígwè Tungsten kpụọ ígwè, nke ihe ndị bụ́ isi mejupụtara ya bụ tungsten carbide na cobalt, mejupụtara 99% nke ihe niile mejupụtara ya na 1% nke ọla ndị ọzọ, ya mere a na-akpọ ya ígwè tungsten, nke a makwaara dị ka carbide simenti, a na-ewerekwa ya dị ka ezé ụlọ ọrụ ọgbara ọhụrụ.

E ji ígwè Tungsten mee ígwè, ọ bụ ihe mejupụtara ya nke nwere ma ọ dịkarịa ala otu ihe mejupụtara ígwè carbide. Tungsten carbide, cobalt carbide, niobium carbide, titanium carbide, na tantalum carbide bụ ihe ndị a na-ahụkarị n'ime ígwè tungsten. Nha ọka nke ihe mejupụtara carbide (ma ọ bụ usoro) na-adịkarị n'etiti 0.2-10 microns, a na-ejikwa ihe njikọ ígwè jikọta mkpụrụ carbide. E ji ígwè ndị a jikọta bụ ọla ígwè, nke a na-akpọkarị cobalt na nickel. Ya mere, e nwere tungsten-cobalt alloys, tungsten-nickel alloys na tungsten-titanium-cobalt alloys.

Ịkpụpụta Tungsten sinter bụ ịpịnye ntụ ahụ n'ime billet, wee banye n'ime ọkụ sintering iji kpoo ya ọkụ ruo okpomọkụ ụfọdụ (okpomọkụ sintering) ma debe ya ruo oge ụfọdụ (oge ijide), wee jụọ ya oyi iji nweta ihe ígwè tungsten nwere ihe ndị achọrọ.

① Tungsten na cobalt simenti carbide

Isi ihe mejupụtara ya bụ tungsten carbide (WC) na binder cobalt (Co). Ọkwa ya bụ "YG" ("siri ike, cobalt" na Hanyu Pinyin) na pasentị nke ọdịnaya cobalt nkezi. Dịka ọmụmaatụ, YG8, nke pụtara nkezi WCo = 8% na nke fọdụrụ bụ tungsten carbide simenti carbide.

②Tungsten, titanium na cobalt simenti carbide

Ihe ndị bụ isi mejupụtara ya bụ tungsten carbide, titanium carbide (TiC) na cobalt. Ọkwa ya bụ "YT" ("siri ike, titanium" na Hanyu Pinyin) na nkezi ọdịnaya nke titanium carbide. Dịka ọmụmaatụ, YT15, pụtara nkezi TiC=15%, nke fọdụrụ bụ tungsten carbide na cobalt ọdịnaya nke tungsten titanium cobalt carbide.

③Tungsten-titanium-tantalum (niobium) carbide

Ihe ndị bụ isi mejupụtara ya bụ tungsten carbide, titanium carbide, tantalum carbide (ma ọ bụ niobium carbide) na cobalt. A na-akpọkwa ụdị carbide a carbide nkịtị ma ọ bụ carbide zuru ụwa ọnụ. Akara ya nwere "YW" ("siri ike" na "nde" na Hanyu Pinyin) tinyere ọnụọgụgụ usoro, dịka YW1.

Ọkpụkpọ Tungsten nwere ọtụtụ ihe ndị dị mma dịka ike siri ike, ike iyi, ike na ike ka mma, ike okpomọkụ, ike ire ere, wdg. Karịsịa ike siri ike ya na ike iyi ya na-agbanweghi agbanwe ọbụlagodi na okpomọkụ nke 500℃, ma ka nwere ike siri ike na 1000℃. A na-ejikarị carbide simentị eme ihe dị ka ihe, dịka ngwaọrụ ntụgharị, ngwaọrụ igwe, ihe eji egwu mmiri, ngwaọrụ na-agwụ ike, wdg. Ọsọ ịkpụ carbide ọhụrụ ahụ hà nhata ọtụtụ narị ugboro nke ígwè carbon.

Oge ozi: Febụwarị-21-2023