Ngwaọrụ carbide e ji simenti rụọ na-achịkwa ngwaọrụ CNC. Na mba ụfọdụ, ihe karịrị 90% nke ngwaọrụ ntụgharị na ihe karịrị 55% nke ngwaọrụ ịkpụ ihe bụ nke ejiri simenti mee. Na mgbakwunye, a na-ejikarị carbide e ji simenti emepụta ngwaọrụ izugbe dịka igwe nkụ ihe na ihe ndị e ji egwe ihe ihu. Ojiji nke carbide e ji simenti rụọ na-amụbakwa na ngwaọrụ dị mgbagwoju anya dịka reamers, end mills, medium na nnukwu modulus gear cutters maka ịkpụ ihe ndị siri ike, na broaches. Arụmọrụ ịkpụ ihe nke ngwaọrụ carbide e ji simenti rụọ bụ ugboro 5 ruo 8 nke ngwaọrụ ígwè dị elu (HSS). Ọnụọgụ ígwè ewepụrụ kwa nkeji nke ọdịnaya tungsten dị ihe dị ka ugboro 5 karịa nke HSS. Ya mere, iji carbide e ji simenti rụọ ọrụ nke ọma dị ka ihe eji arụ ọrụ bụ otu n'ime ụzọ kachasị dị irè iji jiri akụrụngwa mee ihe nke ọma, melite mmepụta ihe, ma melite uru akụ na ụba.

Nhazi nke Ihe Ngwaọrụ Carbide Simented

Dabere na ihe mejupụtara kemịkalụ bụ isi, enwere ike kewaa carbide simenti n'ime carbide simenti dabere na tungsten carbide na carbide simenti dabere na titanium carbonitride (Ti(C,N)), dịka egosiri na Tebụl 3-1.

Carbide simenti nke Tungsten carbide gụnyere:

Tungsten-cobalt (YG)

Tungsten-cobalt-titanium (YT)

Na mgbakwunye carbide dị ụkọ (YW)

Ụdị nke ọ bụla nwere uru na ọghọm nke ya. Carbides ndị agbakwunyere gụnyere tungsten carbide (WC), titanium carbide (TiC), tantalum carbide (TaC), niobium carbide (NbC), wdg, ebe cobalt (Co) bụ usoro ihe eji ejikọta ígwè nke a na-ejikarị eme ihe.

Carbide simenti nke dabere na titanium carbonitride nwere TiC (ụfọdụ nwere carbide ma ọ bụ nitrides ndị ọzọ), yana molybdenum (Mo) na nickel (Ni) dị ka usoro ihe eji ejikọta ígwè a na-ejikarị eme ihe.

Dabere na nha ọka, enwere ike kewaa carbide simenti n'ime:

Carbide nkịtị e ji simenti mee

carbide simenti mara mma

carbide simenti nke nwere ọtụtụ mkpụrụ osisi

Dịka GB/T 2075—2007 si kwuo, akara mkpụrụedemede ndị a bụ ndị a:

HW: Carbide simenti a na-ekpuchighị ekpuchi nke nwere tungsten carbide (WC) nke nha ọka ya bụ ≥1μm

HF: carbide simenti a na-ekpuchighị ekpuchi nke nwere tungsten carbide (WC) nke nha ọka ya ruru <1μm

HT: Carbide simenti a na-ekpuchighị ekpuchi nke nwere titanium carbide (TiC) ma ọ bụ titanium nitride (TiN) ma ọ bụ ha abụọ (a makwaara dị ka cermet)

HC: Carbides ndị a kpọtụrụ aha n'elu nwere ihe mkpuchi

Òtù Mba Nile Maka Nhazi (ISO) kewara carbide simenti ịkpụ n'ime ụdị atọ:

Klas K (K10 ruo K40):

Dakọtara na klas YG nke China (nke mejupụtara WC-Co)

Klas P (P01 ruo P50):

Dakọtara na klas YT nke China (nke mejupụtara WC-TiC-Co)

Klas M (M10 ruo M40):

Dakọtara na klas YW nke China (nke mejupụtara WC-TiC-TaC(NbC)-Co)

A na-eji ọnụọgụgụ dị n'etiti 01 na 50 anọchite anya akara nke otu ọ bụla, nke na-egosi usoro alloys site na ike kachasị elu ruo na ike kachasị ukwuu, maka nhọrọ n'ọtụtụ usoro ịkpụ na ọnọdụ igwe maka ihe dị iche iche. Ọ bụrụ na ọ dị mkpa, enwere ike itinye koodu etiti n'etiti koodu nhazi abụọ dị nso, dị ka P15 n'etiti P10 na P20, ma ọ bụ K25 n'etiti K20 na K30, mana ọ bụghị ihe karịrị otu. N'ọnọdụ pụrụ iche, enwere ike kewaa koodu nhazi P01 ọzọ site na ịgbakwunye ọnụọgụ ọzọ nke ebe decimal kewara, dị ka P01.1, P01.2, wdg, iji matakwuo etu ihe si eguzogide iyi na ike nke ihe maka ọrụ imecha.

Arụmọrụ nke ihe eji arụ ọrụ simenti nke e ji carbide mee

1. Ike Carbide e ji simenti mee nwere ọtụtụ carbide siri ike (dịka WC, TiC), nke na-eme ka ike ya dị elu karịa nke ihe ígwè dị elu. Ka ike carbide e ji simenti mee dị elu, otú ahụ ka ike ya na-esi ike karị, nke na-adịkarị elu karịa nke ígwè dị elu.

Ka ọnụọgụ nke cobalt na-ejikọ elu, otú ahụ ka ike nke alloy ahụ na-ebelata.

Ebe ọ bụ na TiC siri ike karịa WC, alloys WC-TiC-Co nwere ike siri ike karịa alloys WC-Co. Ka ọdịnaya TiC na-abawanye, otú ahụ ka ike ya na-esi elu.

Ịtinye TaC na alloys WC-Co na-eme ka ike sie ike site na ihe dịka 40 ruo 100 HV; itinye NbC na-eme ka ọ dịkwuo elu site na 70 ruo 150 HV.

2. Ike Ike nke carbide e ji simenti mee dị naanị ihe dịka 1/3 ruo 1/2 nke ihe ígwè dị elu.

Ka kọbalt dị elu, otú ahụ ka ike nke alloy ahụ si dị elu.

Alloys nwere TiC nwere ike dị ala karịa ndị na-enweghị TiC; ka ọdịnaya TiC na-abawanye, otú ahụ ka ike ya na-ebelata.

Ịtinye TaC na carbide simenti nke WC-TiC-Co na-eme ka ike ya na-agbanwe agbanwe dịkwuo elu ma na-eme ka akụkụ ya na-eguzogide mgbawa na mgbawa dịkwuo mma. Ka ọdịnaya TaC na-abawanye, ike ọgwụgwụ na-akawanye mma.

Ike nrụgide nke carbide e ji simenti mee dị elu site na 30% ruo 50% karịa nke ígwè dị elu.

3. Ike Ike nke carbide e ji simenti mee dị nnọọ ala karịa nke ígwè dị elu.

Alloys nwere TiC nwere ike dị ala karịa ndị na-enweghị TiC; ka ọdịnaya TiC na-abawanye, ike ya na-ebelata.

N'ime alloys WC-TiC-Co, itinye TaC kwesịrị ekwesị nwere ike ime ka ike sie ike dịkwuo ihe dị ka 10% ma na-echekwa iguzogide okpomọkụ na iguzogide iyi.

N'ihi ike ya dị ala, carbide e ji simenti mee adịghị mma maka ọnọdụ nwere mmetụta siri ike ma ọ bụ mkpọtụ, ọkachasị n'oge obere ọsọ ịkpụ ebe njikọta na mgbawa siri ike karịa.

4. Njirimara Anụ Ahụ nke OkpomọkụOke ike nke carbide e ji simenti rụọ dị ihe dị ka okpukpu abụọ ruo atọ karịa nke ígwè dị elu.

Ebe ọ bụ na ike okpomọkụ nke TiC dị ala karịa nke WC, ihe ndị mejupụtara WC-TiC-Co nwere ike ime ka ike okpomọkụ dị ala karịa ihe ndị mejupụtara WC-Co. Ka ọdịnaya TiC na-abawanye, otú ahụ ka ike okpomọkụ na-eme ka ike okpomọkụ ghara ịdị mma.

5. Nguzogide Okpomọkụ Carbide e ji simenti mee nwere oke iguzogide okpomọkụ karịa ígwè dị elu ma nwee ike ịkpụ ya na 800 ruo 1000°C ma nwee ezigbo iguzogide mgbanwe plastik na oke okpomọkụ.

Ịtinye TiC na-eme ka ike okpomọkụ dị elu dịkwuo elu. Ebe ọ bụ na okpomọkụ dị nro nke TiC dị elu karịa nke WC, ike nke alloys WC-TiC-Co na-ebelata nwayọ nwayọ na okpomọkụ karịa alloys WC-Co. Ka TiC na-abawanye na obere cobalt, otú ahụ ka mbelata ahụ na-ebelata.

Ịtinye TaC ma ọ bụ NbC (nke nwere okpomọkụ dị nro karịa TiC) na-eme ka ike na oke okpomọkụ dịkwuo elu.

6. Njirimara Mgbochi NrapadoOkpomọkụ nrapado nke carbide e ji simenti mee dị elu karịa nke ígwè dị elu, na-eme ka ọ ghara ịdịgide nrapado nke ọma.

Okpomọkụ njikọta nke Cobalt na ígwè dị ala karịa nke WC; ka ọdịnaya cobalt na-abawanye, okpomọkụ njikọta na-ebelata.

Okpomọkụ njikọta TiC dị elu karịa nke WC, yabụ alloys WC-TiC-Co nwere okpomọkụ njikọta dị elu (ihe dị ka 100°C karịa alloys WC-Co). TiO2 e mepụtara n'oge okpomọkụ dị elu n'oge ịkpụcha na-ebelata njikọta.

TaC na NbC nwere okpomọkụ njikọta dị elu karịa TiC, na-eme ka njirimara mgbochi njikọta dịkwuo mma. Njikọ TaC na ihe eji arụ ọrụ dị obere naanị na ọkara nke WC.

7. Nkwụsi Ike KemịkalụNguzogide iyi nke ngwaọrụ carbide e ji simenti mee nwere njikọ chiri anya na nkwụsi ike anụ ahụ na nke kemịkalụ ha n'oge okpomọkụ ọrụ.

Okpomọkụ oxidation nke carbide simenti dị elu karịa nke ígwè dị elu.

Okpomọkụ oxidation nke TiC dị elu karịa nke WC, yabụ alloys WC-TiC-Co na-enweta obere ibu oxidation na okpomọkụ dị elu karịa alloys WC-Co; ka TiC na-abawanye, otú ahụ ka iguzogide oxidation si esi ike.

Okpomọkụ oxidation nke TaC dịkwa elu karịa nke WC, ihe ndị mejupụtara ya na TaC na NbC emeela ka iguzogide oxidation dị elu ka mma. Agbanyeghị, ọdịnaya kọbalt dị elu na-eme ka oxidation dịkwuo mfe.

Gịnị mere ị ga-eji họrọ Chengduhuaxin Carbide?

Chengduhuaxin Carbide pụtara ìhè n'ahịa n'ihi nkwa ya maka ịdị mma na ihe ọhụrụ. A na-emepụta agụba kapeeti tungsten carbide ha na agụba tungsten carbide maka arụmọrụ ka mma, na-enye ndị ọrụ ngwaọrụ ndị na-enye ịkpụcha dị ọcha, nke ziri ezi ma na-anagide nrụgide nke ojiji ụlọ ọrụ siri ike. Site n'ilekwasị anya na ịdịte aka na arụmọrụ, agụba Chengduhuaxin Carbide na-enye ngwọta zuru oke maka ụlọ ọrụ chọrọ ngwaọrụ ịkpụcha a pụrụ ịdabere na ya.

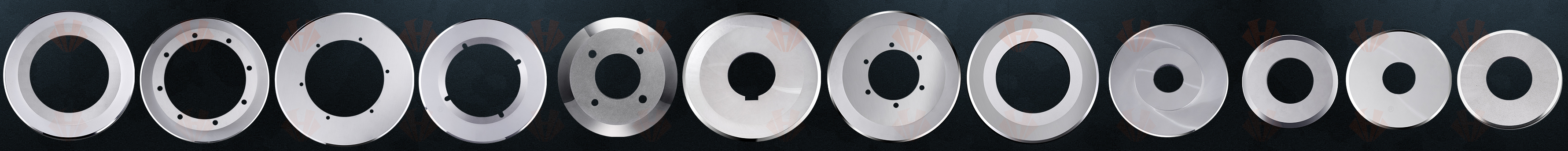

CHENGDU HUAXIN CEMENTED CARBIDE CO.,LTD bụ ọkachamara na-eweta ma na-emepụta ngwaahịangwaahịa tungsten carbide,dị ka mma ntinye carbide maka ịrụ ọrụ osisi, carbidemma okirikirimakamkpara nzacha ụtaba na sịga na-amịpụ, mma gburugburu maka ịkpụcha katọn a kpụchara akpụkọ,agụba atọ nwere oghere/agụba oghere maka nkwakọ ngwaahịa, teepu, ịkpụ ihe nkiri dị gịrịgịrị, agụba eriri maka ụlọ ọrụ akwa wdg.

Site na mmepe ihe karịrị afọ iri abụọ na ise, ebupụla ngwaahịa anyị na US A, Russia, South America, India, Turkey, Pakistan, Australia, Southeast Asia wdg. Site na ezigbo mma na ọnụ ahịa asọmpi, ndị ahịa anyị na-akwado àgwà ọrụ siri ike na nzaghachi anyị. Anyị ga-achọkwa ịmalite mmekọrịta azụmaahịa ọhụrụ na ndị ahịa ọhụrụ.

Kpọtụrụ anyị taa, ị ga-enweta uru dị na ezigbo mma na ọrụ sitere na ngwaahịa anyị!

Ajụjụ ndị ahịa na azịza Huaxin

Nke ahụ dabere na ọnụọgụgụ ya, nke na-abụkarị ụbọchị ise ruo iri na anọ. Dịka onye na-emepụta agụba ụlọ ọrụ mmepụta ihe, Huaxin Cement Carbide na-eme atụmatụ mmepụta ya site na iwu na arịrịọ ndị ahịa.

Ọ na-abụkarị izu 3-6, ọ bụrụ na ị rịọ maka mma igwe ahaziri ahazi ma ọ bụ agụba ụlọ ọrụ mmepụta ihe nke na-adịghị na ngwa ahịa n'oge ịzụrụ ihe. Chọta Ọnọdụ Ịzụta na Nnyefe Sollex ebe a.

ọ bụrụ na ị rịọ maka mma igwe ma ọ bụ agụba ụlọ ọrụ ahaziri ahazi nke na-adịghị na ngwa ahịa n'oge ịzụrụ ihe. Chọta Ọnọdụ Ịzụta na Nnyefe SollexEbe a.

Ọtụtụ mgbe, T/T, Western Union...ego nkwụnye ego mbụ, A na-akwụ ụgwọ mbụ niile sitere n'aka ndị ahịa ọhụrụ. Enwere ike ịkwụ ụgwọ ndị ọzọ site na akwụkwọ ọnụahịa...kpọtụrụ anyịịmatakwu

Ee, kpọtụrụ anyị, mma ụlọ ọrụ mmepụta ihe dị iche iche, gụnyere mma gburugburu dị n'elu, mma gburugburu dị n'okpuru, mma siri ike/ethed, mma gburugburu dị n'ime, mma kwụ ọtọ, mma guillotine, mma dị n'ọnụ, mma agụba nwere akụkụ anọ, na agụba trapezoidal.

Iji nyere gị aka inweta agụba kacha mma, Huaxin Cement Carbide nwere ike inye gị ọtụtụ agụba ị ga-anwale na mmepụta. Maka ịkpụ na ịtụgharị ihe ndị na-agbanwe agbanwe dị ka ihe nkiri plastik, foil, vinyl, akwụkwọ, na ndị ọzọ, anyị na-enye agụba ndị na-agbanwe agbanwe gụnyere agụba ndị nwere oghere na agụba ndị nwere oghere atọ. Zitere anyị ajụjụ ma ọ bụrụ na ịchọrọ agụba igwe, anyị ga-enyekwa gị onyinye. Ihe atụ maka mma emere maka ya adịghị, mana ị nwere ike ịtụ ọnụọgụ kacha nta nke iwu.

E nwere ọtụtụ ụzọ ga-esi mee ka mma na agụba ụlọ ọrụ gị dị ogologo ma dịgide ogologo ndụ. Kpọtụrụ anyị ka ị mara otu esi eji mma igwe eme ihe nke ọma, ọnọdụ nchekwa, iru mmiri na okpomọkụ ikuku, na mkpuchi ndị ọzọ ga-esi chebe mma gị ma mee ka ha dị mma.

Oge ozi: Julaị-23-2025